1. Computerization in analysis and design, the machine is well in stability and easy for maintenance.

2. Conformed to human engineering in design, it features easy and friendly operation.

3. The well-interconnected oil circuit by electric control can reduce waiting time, quicken production rate, and promote productivity.

4. Number of various stations may be optionally chosen for small quantity but greater in variety, or mass production.

5. The devised C-shaped structure that strengthens cooling system suits particularly the need for reinforced cooling effect.

6. The multi-station mechanism is suitable for numerous molds to work in production line. It saves the time for the mold-change and extends the length of cooling time. The working efficiency is highly enhanced.

7. Specially designed, the oil pressure circuit board is simple in structure. The function description of various switches is clearly indicated.

8. Product: Specialized in producing various kinds of one / two / three- color outsoles for sport shoes, leisure shoes, slippers, sandals, man’s and lady’s shoes in general, etc.

9. Material: Suitable for all kinds of thermoplastic raw materials, foaming or non-foaming, such as PVC and TPR.

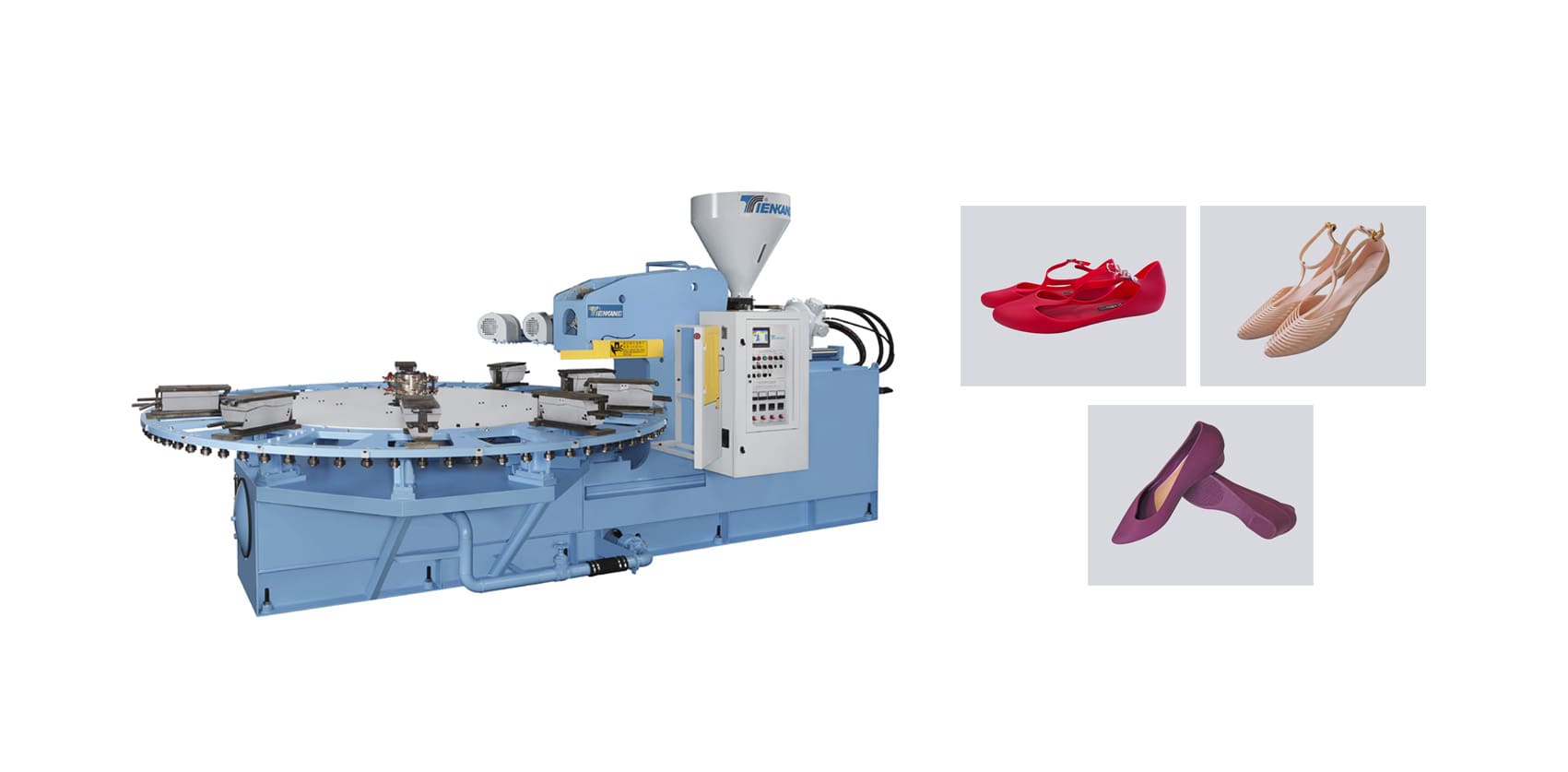

AUTOMATIC ROTARY TYPE PVC SHOES AIR BLOWING INJECTION MOLDING MACHINE. Single color PVC with air blowing and Auto mold opening system

Rotary One-Color Sole/ Plastic shoe injection molding machine for production of various type of one-color silpper,sandal,full shoes...etc.

Applicable material : Foaming, compact, transparent, air-blow thermo pastic materials such as PVC,TPR