Compression molded EVA (Phylon):

The process of making EVA soles by compression molding is not a new technology. In fact, this manufacturing method has lasted for many years because it provides the most consistent control over the size of EVA soles, giving them a detailed texture and a clear, sharp profile. Although this manufacturing method consumes more energy during the repeated heating and cooling process, and is also less productive than EVA injection method, it is still used in the production of footwear. The rapid development of knitting shoe uppers has stimulated the blooming of fashionable athletic shoes. Sneakers are no longer just for sport, it is more like a reflection of personal style. The soles of athletic shoes play an important role in bringing out the complete image. EVA soles are often complex in design and even have exaggerated appearance. To create such EVA soles, compression molding is a better option. However, the traditional molding process is more labor intensive. Shoe factories look for an automated machine to solve this problem and improve the production efficiency. Tien Kang has developed an automatic rotary EVA sole compression machine to meet this demand.

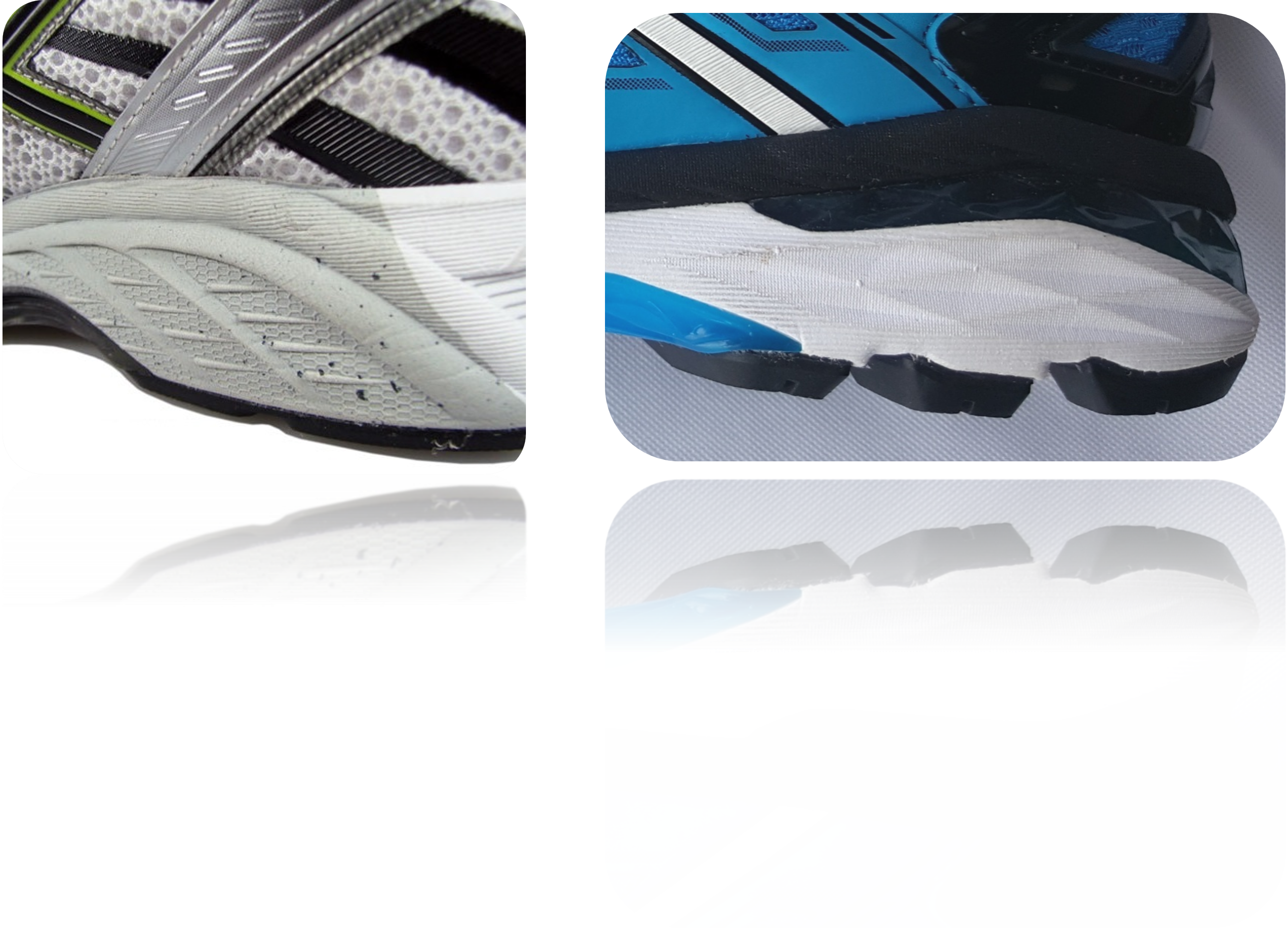

To get sharp texture, lines and design on shoes, which cannot be done by the process of EVA injection

To get most stabilized size and profile

This is the earliest molding process used on making EVA midsoles and outsoles with a high stability of sole dimension and the best clarity of the pattern and texture.

This process is capable to have an accurate profile and dimension at each individual area in order to attach all components with good looking. Basic on rotary structure,

molds exchanging are all automatic, and one man operates 20 sets of molds with easier production management.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.